Vertical Laminar Flow Hood vs Horizontal Laminar Flow Hood

Laminar air flow hoods are perfect for those kinds of experiments or work that do not require the user to be protected. Examples of this could include tissue culture, media pouring, etc. But these hoods also differ depending on the direction of airflow within the hood. This makes them useful for differing purposes as well.

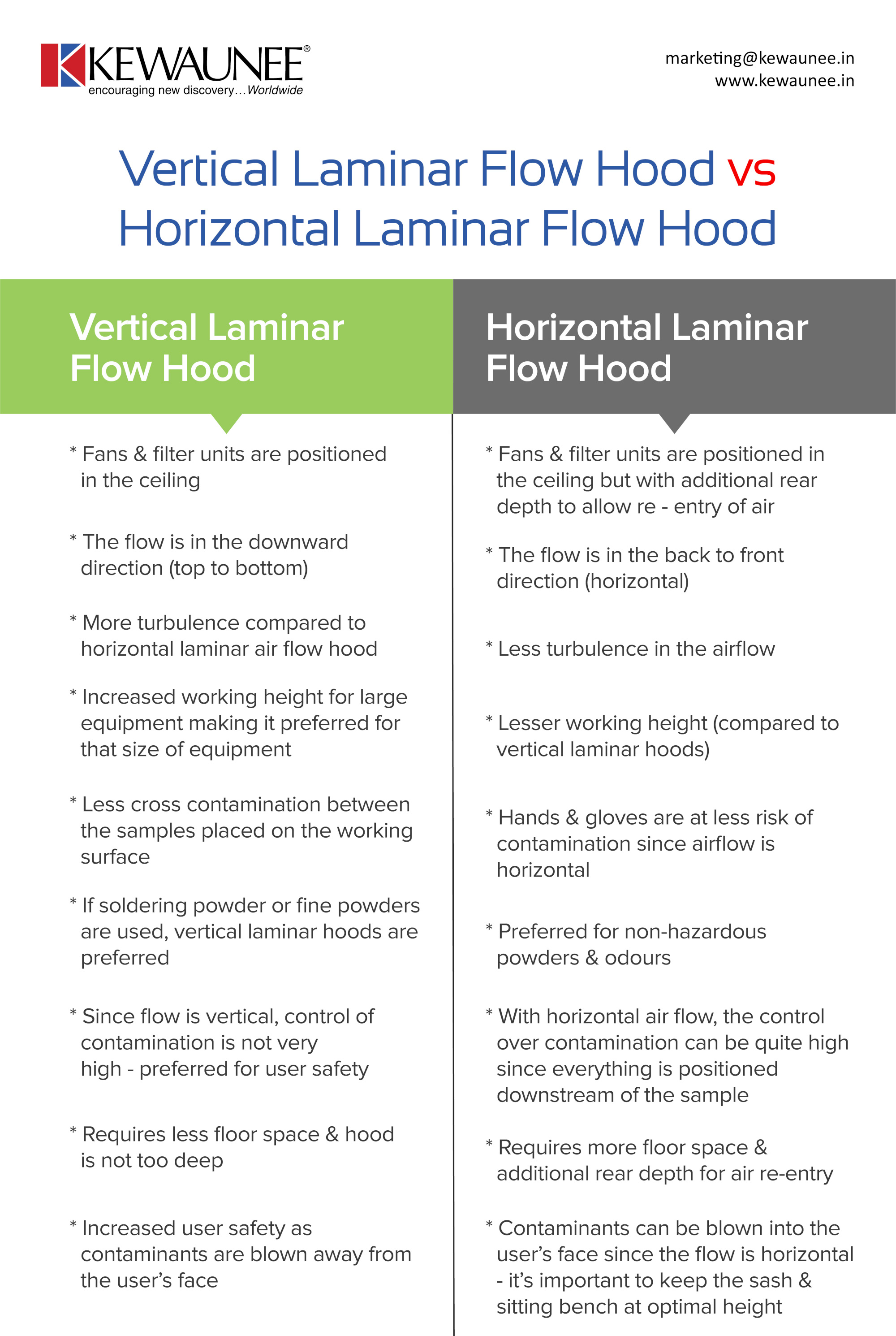

In this infographic, we’re discussing the major differences between horizontal airflow & vertical airflow hoods and how to decide what purpose to use them for.

| Vertical Laminar Flow Hood | Horizontal Laminar Flow Hood |

| Fans & filter units are positioned in the ceiling | Fans & filter units are positioned in the ceiling but with additional rear depth to allow re-entry of air |

| The flow is in the downward direction (top to bottom) | The flow is in the back to front direction (horizontal) |

| More turbulence compared to horizontal laminar air flow hood | Less turbulence in the airflow |

| Increased working height for large equipment making it preferred for that size of equipment | Lesser working height (compared to vertical laminar hoods) |

| Less cross contamination between the samples placed on the working surface | Hands & gloves are at less risk of contamination since airflow is horizontal |

| If soldering powder or fine powders are used, vertical laminar hoods are preferred | Preferred for non-hazardous powders & odours |

| Since flow is vertical, control of contamination is not very high – preferred for user safety | With horizontal air flow, the control over contamination can be quite high since everything is positioned downstream of the sample |

| Requires less floor space & hood is not too deep | Requires more floor space & additional rear depth for air re-entry |

| Increased user safety as contaminants are blown away from the user’s face | Contaminants can be blown into the user’s face since the flow is horizontal – it’s important to keep the sash & sitting bench at optimal height |

Comments are closed.