How To Select The Right Fume Hood For Your Laboratory

Researchers and scientists deal with harmful chemicals, hazardous materials, and poisonous gases daily. For any organisation and institution hosting laboratories, the safety of the lab users and of the lab is the top priority.

Fume hoods are the common and reliable engineering control deployed for safe labs. But, selecting a fume hood can be a confusing task. Fume hoods come in various configuration and sizes complicating the choice.

But, don’t you worry. In this guide, we’ll walk-you through the five important aspects you need to check for when selecting your next fume hood.

First, let’s get some basics in place.

WHAT IS THE PURPOSE OF A FUME HOOD?

Ventilation devices are used to capture and remove the contaminants (gas, vapour, or dust) away from the users and out of the laboratory. Fume hood (fume cupboard or fume closet) is a local ventilation device found in all laboratories.

Fume hoods control contamination by drawing air through the face of the fume hood and away from the users and labs. Through ventilation fume hoods minimise the risk of contamination.

WHAT ARE FUME HOODS MADE OF?

We know fume hoods work by drawing the air and contaminants out of the user zone. Modern fume hoods, like Kewaunee’s Supreme Air Venturi, comes with many controls and parts for enhanced safety. For now, we’ll focus on three important components – sash, baffles, and fume hood body.

SASH is a moveable panel on front portion of the fume hoods – often referred to as the fume hood door or window. Sash provides a protective barrier between the lab user and the experiment. The common sash configurations are – vertical, horizontal, and combination sash (vertical + horizontal).

BAFFLE is the slotted openings along the back of the hood. Baffles work in tandem with the sash to control the air flow in the fume hood and keep the airflow uniform. By eliminating the dead spots and reverse airflow (into the labs), baffles play an important role in safety and fume hood efficiency. In older fume hoods, baffles were moveable partitions, but modern fume hood like Supreme Air Venturi comes with fixed baffles.

BODY comprises the fume hood exterior and the interior. The fume hood body contains the contaminants. Well-designed exterior will have a contoured entry (aerodynamic design) to assist airflow into the hood and improve hood performance. The material of construction (MOC) is an important consideration for fume hood, specifically the interior liner material. Since chemicals and gases can corrode the interiors and exterior, MOCs resistant to work being conducted in the fume hood is critical when selecting your fume hood.

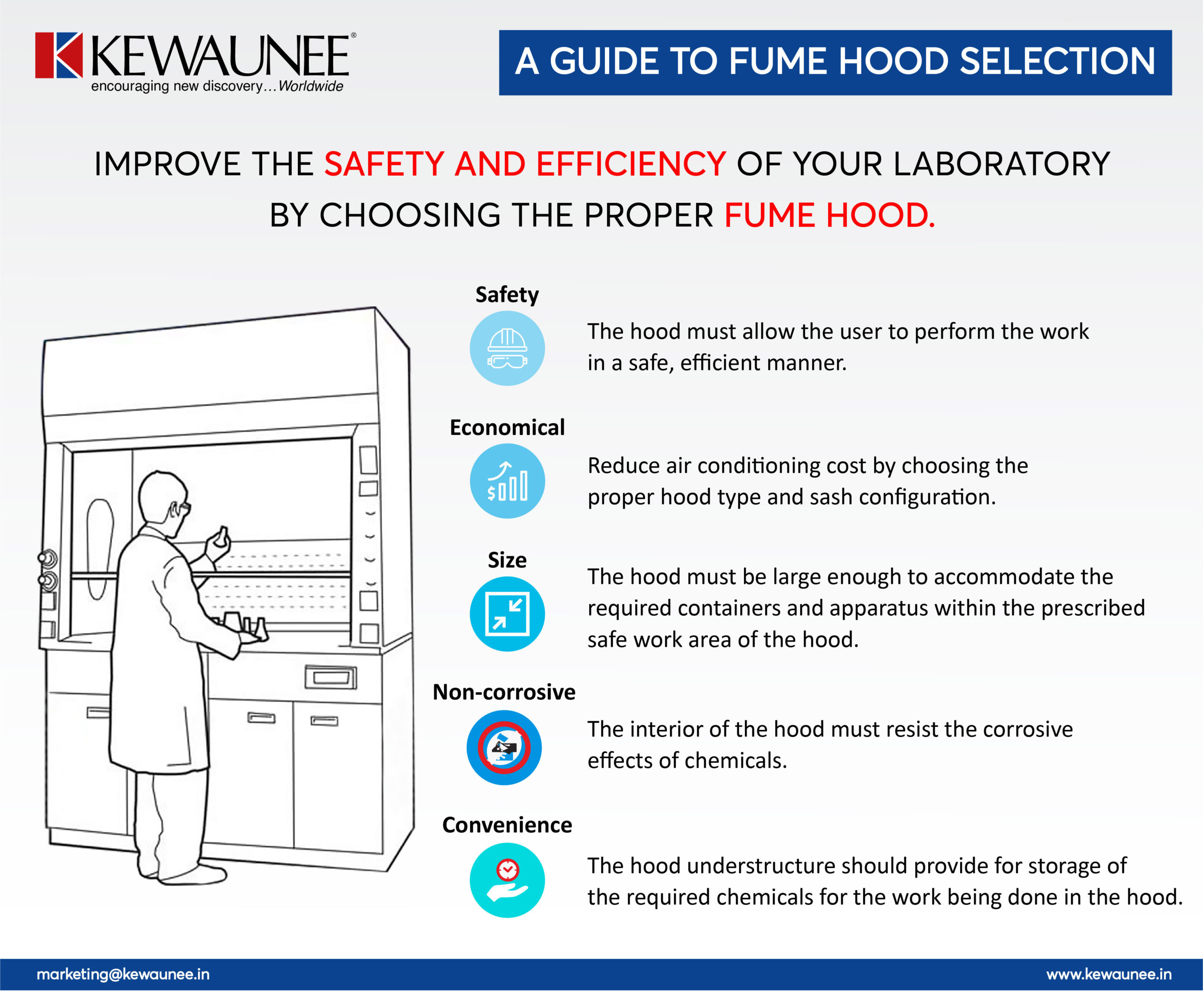

FIVE ESSENTIALS THINGS TO CONSIDER FOR FUME HOOD SELECTION

With a basic understanding of fume hood, let’s now explore the essentials to consider whilst selecting a fume hood. Selection of the proper fume hood to use in a laboratory should factor in two interrelated considerations:

The five important aspects you need to check for when selecting your next fume hood are:

1. SAFETY

Safety of the fume hood can leave you in a twist. There are many aspects affecting the safety – fume hood design, material of construction, sash positions, exhaust efficiency, user-friendly features, etc. Many accredited bodies (SEFA, ASHRAE, Underwriters Laboratories, National Fire Protection Association, etc.) are working hard to specify the safety and quality standards.

Choosing fume hoods with the highest safety certification and compliance is a smart way to go.

2. ECONOMICS

According to a research, a lab consumes 5 times the energy as an equivalent office space. As the environmental norms are tightening and organisations are becoming conscious of their energy consumption, fume hoods can play a significant part in reducing the energy bills and carbon footprint. Fume hood exhaust requirements affect the total cost of energy – the cost of heating and cooling the air exhausted by the hood.

Choosing the proper hood designed for high efficiency at lower exhaust can help reduce these costs

.

3. SIZE

Fume hood must be large enough to accommodate the containers and apparatus within the prescribed safe work area of the hood (6″ behind the plane of the sash). The configuration of the hood should allow containers movement in and out of the hood with ease.

The sash opening of the hood must allow enough access for safe manipulation of the containers and apparatus within the hood.

4. NON-CORROSIVE

The interior of the hood must resist the corrosive effects of chemical fumes, vapors, and condensation particulates. Fume hood designs preventing contaminants collection and deposit on the interior surface should be high on your agenda for safety and higher ROI.

The inner liner materials should be resistant to the chemical exposure and corrosion resistance in the fume chamber.

5. CONVENIENCE

Modern fume hoods allow for convenience of users besides safety. What may seem a minor aspect can affect the lab environment.

The important convenience factors to consider are :

SUMMING UP

Here are the important points:

Download for free.

Kewaunee Guide To FumeHood Selection

Send download link to:

Comments are closed.