A Guide to Technical Feasibility and Conceptualization in Industrial Projects

Embarking on an industrial project requires a meticulous roadmap from the outset. Technical feasibility and conceptualization play pivotal roles in steering the project towards success.

This comprehensive guide will navigate through the intricacies of these crucial initial stages, offering insights into the planning, assessment, and decision-making processes that pave the way for a triumphant industrial project.

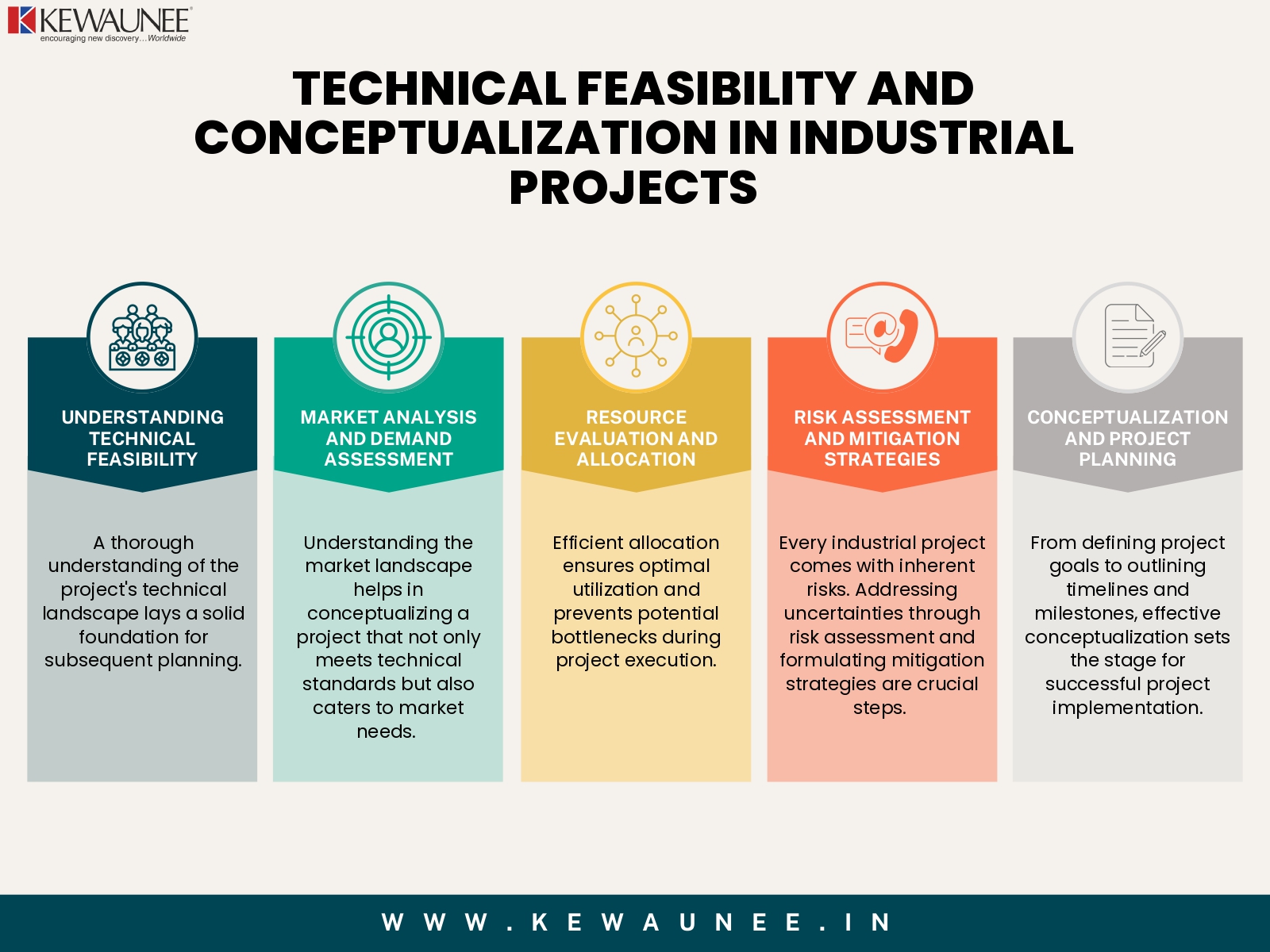

1. Understanding Technical Feasibility

Before delving into the conceptualization phase, it’s paramount to assess the technical feasibility of the project. A thorough understanding of the project’s technical landscape lays a solid foundation for subsequent planning.

In this phase, a detailed analysis of technological requirements is imperative. This involves assessing whether the existing technology can support the project’s objectives or if new technology needs to be developed. Understanding resource availability, including skilled personnel and materials, is crucial to ensuring a smooth technical implementation.

2. Market Analysis and Demand Assessment

Technical feasibility should align with market dynamics and demands. Understanding the market landscape helps in conceptualizing a project that not only meets technical standards but also caters to market needs. This step is instrumental in crafting a project with sustained relevance and success.

Market analysis involves studying market trends, identifying potential competitors, and assessing the demand for the proposed project. Demand assessment ensures that the project aligns with consumer needs and is positioned to meet future market demands. Integrating technical and market considerations is key to a project’s long-term viability.

3. Resource Evaluation and Allocation

Conceptualizing an industrial project requires a realistic evaluation of available resources. Efficient allocation ensures optimal utilization and prevents potential bottlenecks during project execution. A well-thought-out resource plan is integral to the project’s overall feasibility.

Resource evaluation involves a comprehensive analysis of the financial resources required for the project. Human resources, including skilled personnel and project management expertise, are equally crucial. Technological resources encompass the tools and equipment necessary for project implementation. Effective allocation ensures that each resource is maximized to contribute to project success.

4. Risk Assessment and Mitigation Strategies

Every industrial project comes with inherent risks. Addressing uncertainties through risk assessment and formulating mitigation strategies are crucial steps. Proactive risk management contributes to project resilience, ensuring that unexpected challenges are met with strategic solutions.

Risk assessment involves identifying potential threats to project success, such as technical challenges, market fluctuations, or unforeseen external factors. Mitigation strategies are proactive measures to address and minimize identified risks. A well-structured risk management plan enhances the project’s adaptability and resilience throughout its lifecycle.

5. Conceptualization and Project Planning

With a solid understanding of technical feasibility, market dynamics, resource availability, and risk factors, the conceptualization phase begins. From defining project goals to outlining timelines and milestones, effective conceptualization sets the stage for successful project implementation.

Conceptualization involves synthesizing technical and market insights into a cohesive project plan. Defining clear project goals and objectives ensures that every team member understands the project’s overarching purpose. Project planning includes creating a timeline, setting milestones, and allocating tasks, providing a roadmap for efficient project execution.

Summary

Navigating success in industrial projects hinges on a well-defined process of technical feasibility assessment and conceptualization. Understanding the technical landscape, aligning with market demands, evaluating and allocating resources judiciously, addressing risks, and translating ideas into a robust project plan are all integral components.

This comprehensive guide underscores the significance of a meticulous approach in the initial stages, laying the groundwork for a successful industrial project. By navigating through the complexities of technical feasibility and conceptualization, project stakeholders can embark on a journey that maximizes efficiency, minimizes risks, and ultimately leads to the realization of project goals.

Comments are closed.