The Importance of Proper Ventilation in the Laboratory

Proper ventilation is essential for the safety and health of laboratory workers and the integrity of experiments. It ensures that hazardous materials and chemicals are removed from the laboratory and that fresh air is brought in.

In this blog, we will discuss the importance of proper ventilation in the laboratory, the types of ventilation systems available, factors to consider when designing a ventilation system, safety and compliance, ventilation equipment, and maintenance and upkeep.

Introduction

Proper ventilation is essential for the safety and health of laboratory workers and the integrity of experiments. It ensures that hazardous materials and chemicals are removed from the laboratory and that fresh air is brought in.

The purpose of proper ventilation in the laboratory is to remove hazardous materials and chemicals and bring in fresh air to maintain a safe and healthy environment for laboratory workers.

Inadequate ventilation can lead to health hazards for laboratory workers, such as respiratory problems and chemical exposure, and can also compromise the integrity of experiments.

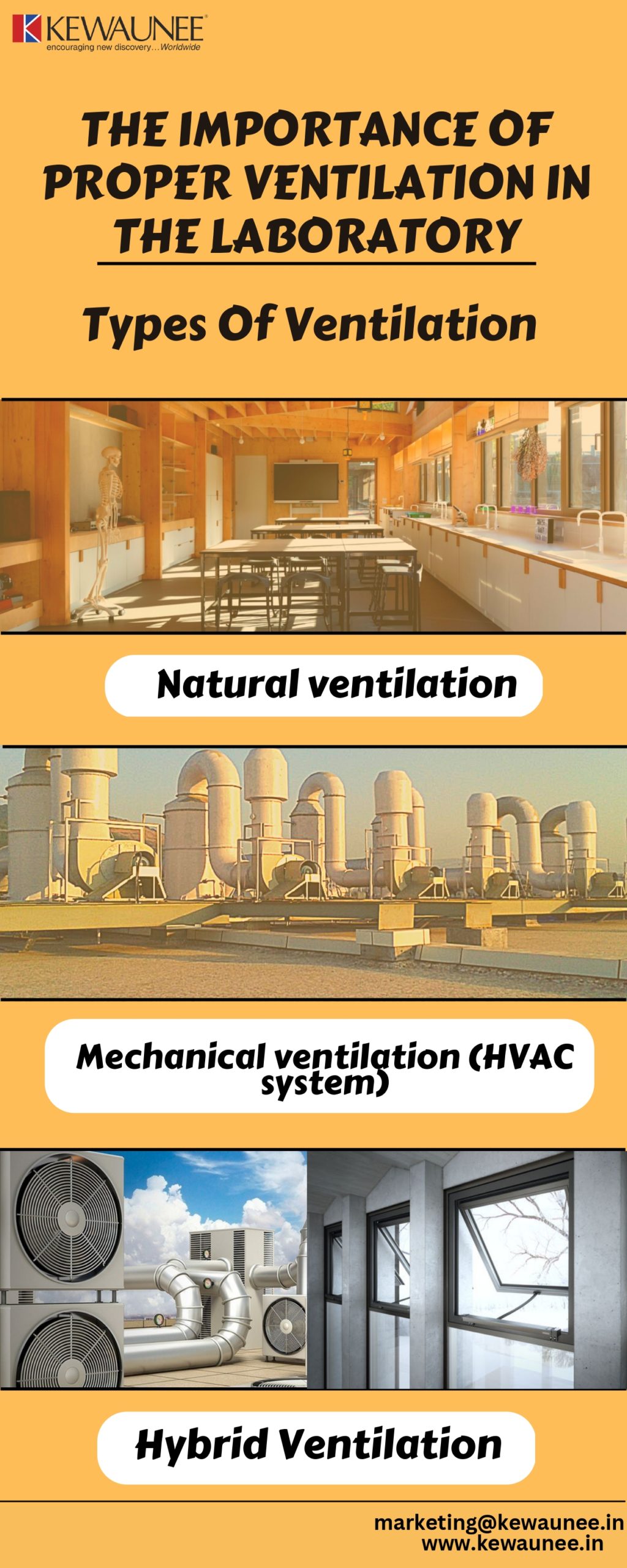

II. Types of Ventilation systems

Natural ventilation

Natural ventilation relies on natural forces such as wind and temperature differences to bring in fresh air and remove hazardous materials and chemicals.

Mechanical ventilation (HVAC system)

Mechanical ventilation, also known as HVAC system, uses fans, ducts, and filters to bring in fresh air and remove hazardous materials and chemicals.

Hybrid ventilation

Hybrid ventilation combines both natural and mechanical ventilation to provide an optimal ventilation solution for the laboratory.

Factors to Consider when designing a ventilation system

Laboratory layout and usage

The layout and usage of the laboratory will determine the type of ventilation system and equipment required.

Airflow and air exchange rate

The airflow and air exchange rate are crucial in determining the effectiveness of the ventilation system.

Filtration and air cleaning

Filtration and air cleaning equipment is necessary to remove hazardous materials and chemicals from the air.

Noise level

Noise level should also be taken into consideration as it can be a distraction and cause discomfort for laboratory workers.

Safety and Compliance for Lab Ventilation

OSHA standards

OSHA has specific standards for laboratory ventilation to ensure the safety and health of laboratory workers.

NFPA standards

NFPA also has specific standards for laboratory ventilation to ensure the safety and health of laboratory workers.

Compliance with local building codes

It is important to ensure compliance with local building codes when designing and installing a ventilation system.

Ventilation Equipment

Fume hoods

Fume hoods are essential for the safe handling of hazardous materials and chemicals. They use airflow to remove hazardous materials and chemicals from the laboratory.

HVAC systems

HVAC systems are used to control temperature, humidity and air quality in the laboratory.

Other equipment

Other equipment that can be used for proper ventilation includes air diffusers, dampers, and exhaust fans.

Maintenance and Upkeep

Regular inspections and maintenance

Regular inspections and maintenance are essential for the proper functioning of the ventilation system and equipment.

Upkeep of filters, ductwork, and equipment

Proper upkeep of filters, ductwork, and equipment is necessary to ensure the effectiveness of the ventilation system.

Proper use and operation

Proper use and operation of the ventilation system and equipment is necessary to ensure the safety and health of laboratory workers.

Conclusion

Proper ventilation is essential for the safety and health of laboratory workers and the integrity of experiments. It ensures that hazardous materials and chemicals are removed from the laboratory and that fresh air is brought in.

Proper design, installation, and maintenance of ventilation systems and equipment is crucial to ensure the safety and health of laboratory workers and the integrity of experiments.

Laboratory managers and designers should prioritize proper ventilation in their laboratory spaces by ensuring proper design, installation, and maintenance of ventilation systems and equipment. This will help to maintain a safe and healthy environment for laboratory workers and the integrity of experiments.

In conclusion, proper ventilation is an essential aspect of laboratory design and operation. It ensures that hazardous materials and chemicals are removed from the laboratory and that fresh air is brought in.

There are different types of ventilation systems available, such as natural, mechanical, and hybrid ventilation. Factors to consider when designing a ventilation system include laboratory layout and usage, airflow and air exchange rate, filtration and air cleaning, and noise level. Compliance with OSHA, NFPA and local building codes is also crucial.

Additionally, proper maintenance and upkeep of ventilation systems and equipment is necessary to ensure the safety and health

Comments are closed.