A Guide To Choosing The Right Fume Hood Liner Material

In a laboratory, the requirements to maintain the health, comfort, safety, and productivity are distinct and unique. When you decide to embark on a new laboratory project or renovation of an existing lab, planning & designing is one of the critical steps.

One critical element of the lab design is to choose the fume hoods.

Laboratory fume hoods are one of the most reliable engineering controls in the laboratory. Fume hoods protect lab users by containing vapours, dusts, and gases generated within the hood. Fume hoods remove the fumes as air flows into the hood and then out via the laboratory exhaust system.

But selecting a fume hood can be a confusing task. Fume hoods come in various configuration and sizes complicating the choice. Additionally, another key element to consider is the liner material of the fume hood.

Depending on the nature of the research and the chemicals used in the research centre, the choice of the liner material may vary. The right choice will play a significant role on the safety and the longevity of the fume hoods.

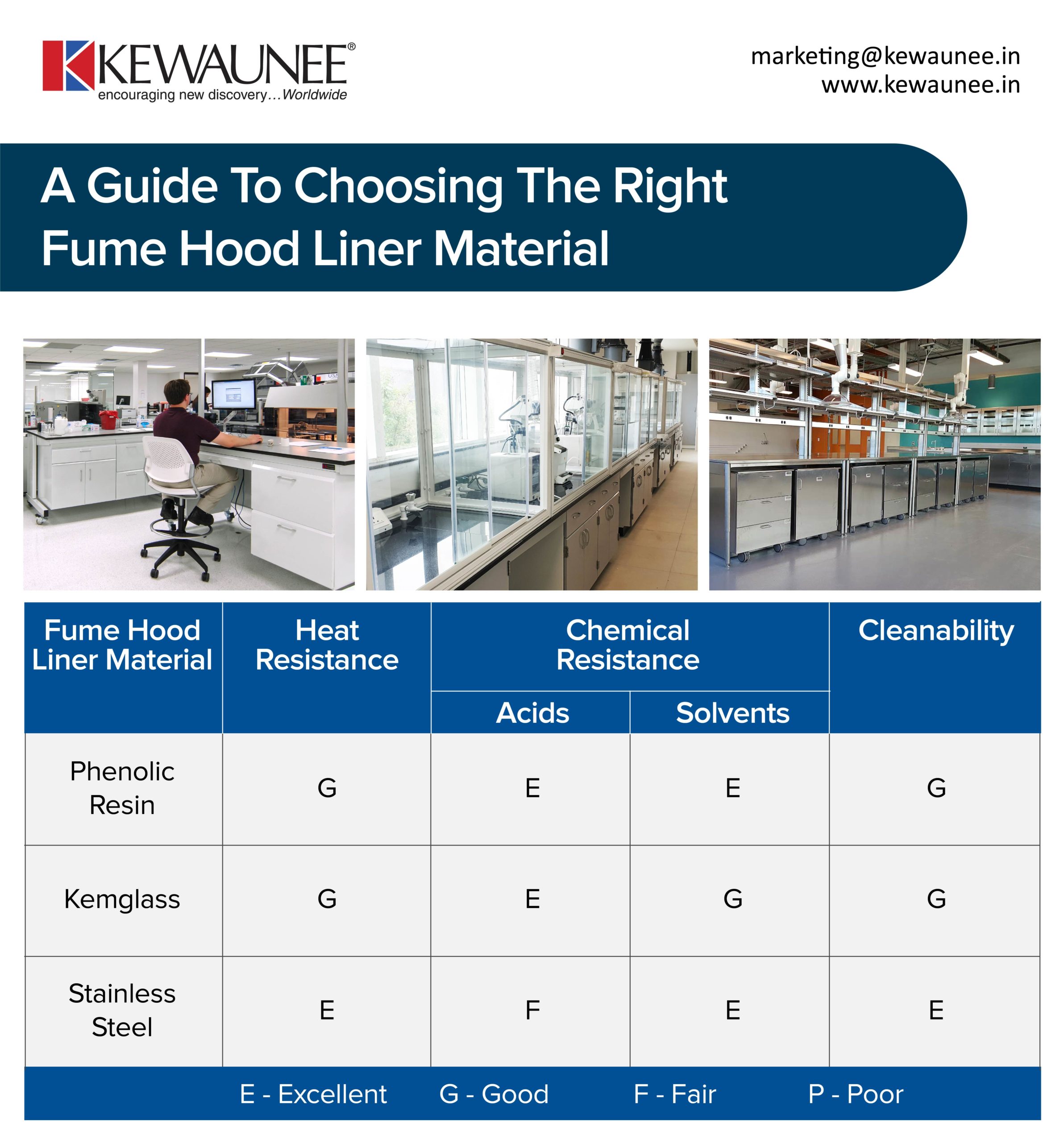

Now, let’s explore the commonly used fume hood liner materials and their application:

| Fume Hood Liner Material | Heat Resistance | Chemical Resistance | Cleanability | |

| Acids | Solvents | |||

| Phenolic Resin | G | E | E | G |

| Kemglass | G | E | G | G |

| Stainless Steel | E | F | E | E |

| E = Excellent G = Good F = Fair P = Poor | ||||

Note:

- Kemglass (G): Kemglass is white fiberglass reinforced polyester sheet material.

- Phenolic Resin (T) liner is reinforced with cellulose fibers and is surfaced with white melamine material. The brown phenolic resin is visible at the edges of the sheet material.

- Type 304 stainless steel (S) is 14-gauge stainless steel sheet with a No.4 finish

Comments are closed.