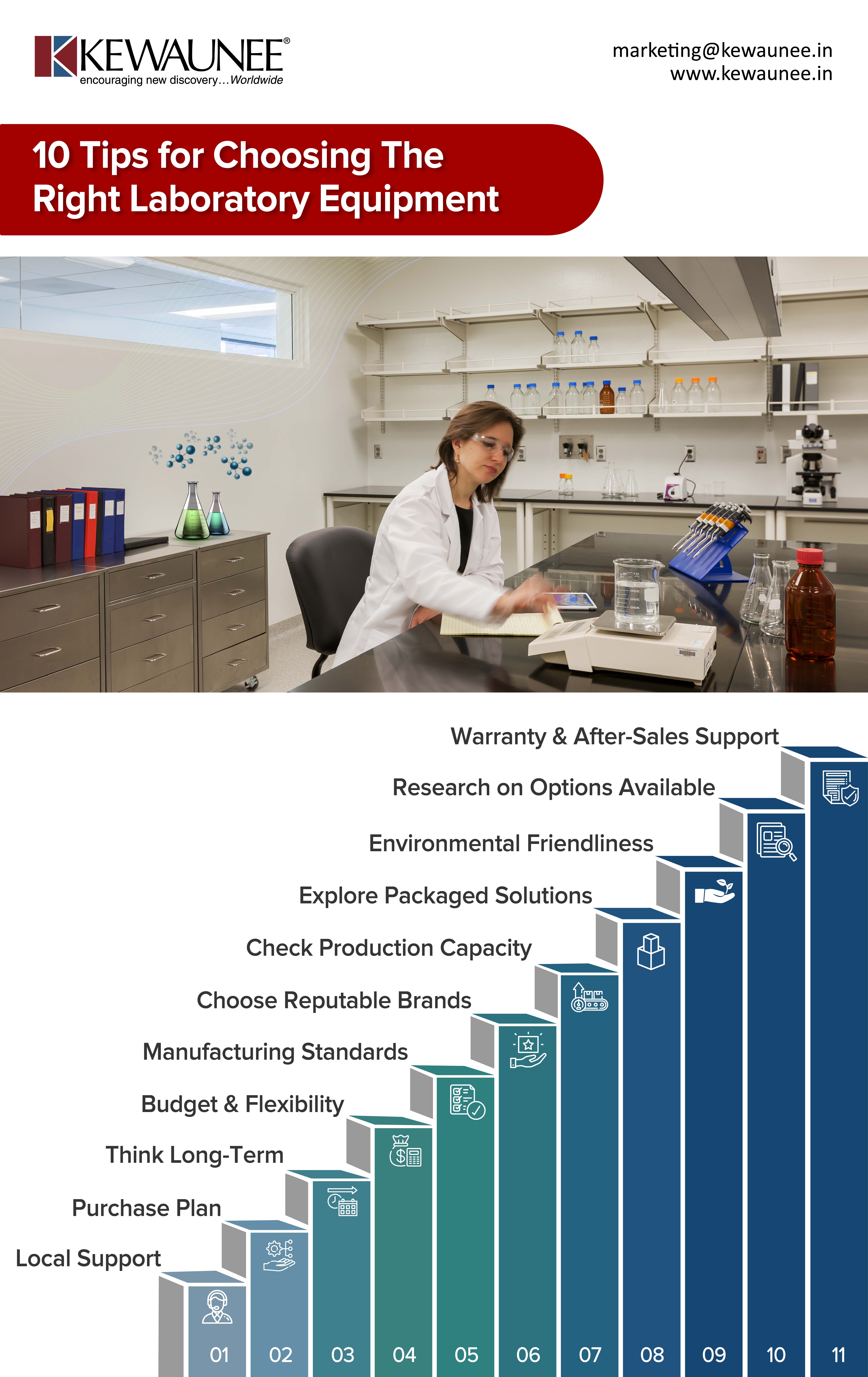

10 Tips For Choosing The Right Laboratory Equipment

The right lab equipment is a must for successfully running a research laboratory. Typically, when you are setting up a new lab, or refurbishing an existing one, you face the choice of choosing the right equipment for your laboratory.

Well, in both the cases, the task can be extremely confusing and challenging. There are many options to consider depending upon the experiment. The specifications may vary and so does the cost. Your equipment shopping expedition may turn out to be an extremely frustrating experience.

What’s even more important is, it’s not just the right equipment which you must focus on, but also the right safety precautions. In this blog, we will help you with the key tips on choosing the right equipment.

1) Purchase Plan

Start with a purchase plan by making an inventory of equipment required. A purchase plan will give a clear view into what’s required, mandatory, and optional. You may also want to cross check the plan inventory to see if some of the equipment are already available.

2) Research on Options Available

Identify the top 3 vendors of the equipment and visit their website or online store to check for options available. Sometimes, a better option than what you considered might be available in the market. Check on the product features & specifications, the ease of use considering researchers comfort, and importantly the power requirement & consumption. Also check the available lab space, against the equipment requirements.

3) Choose Reputable Brands

Safety is of paramount importance in your laboratory. Shortlist the equipment suppliers with reputable brands and a proven history of quality products.

4) Warranty & After-Sales Support

In addition to equipment safety and quality, also research on after sales support and warranty. Timely support and guarantee of resolution are critical to smooth functioning of the laboratory.

5) Check Production Capacity

Delayed equipment may adversely impact your laboratory project planning and timelines. Reputed manufacturers have well-oiled supply chain mechanism with adequate production capacity to meet the demands.

6) Manufacturing Standards

Check for the standards employed by the manufacturers in the production process. Focus on what safety, quality, and process are being followed.

7) Local Support

Does the lab equipment manufacturer produce the equipment locally or do they import it from another country? Finding this out is important, as available of replacement parts locally and faster on-site support ensures better resolution.

7) Think Long-Term

An equipment is not a short-term purchase, but a long-term investment. Choose equipment that are durable and can perform for a long-time without issues.

8) Environmental Friendliness

Given the focus on sustainability in laboratories, the choice of “green equipment” may be limited. However, it pays off in the long-term and in many jurisdictions mandated by law to reduce the carbon footprint.

9) Explore Packaged Solutions

If your project is of a larger scope, then you may consider packages solutions like turnkey. Due to bulk orders and lower overheads, manufacturers may offer better pricing structures in a packaged deal.

10) Budget & Flexibility

Finally, based on all the research, estimate a budget for the equipment purchase. If the price sheet is not available on the vendor’s website, check with them or speak to your supply chain team, who may have it already. Build adequate flexibility into the budget to account for variants and unplanned additions.

Hopefully, now you are better armed with tips and strategies for your next lab project. Start your lab journey with our product explorer. Or talk to our experts who’ll help you design and plan the right-fit solutions for your laboratory.

Comments are closed.